Our

Courses

Ourlocations

Nationwide training

Delivered 24/7 at your place or ours

- Auckland

- Christchurch

- Cromwell

- Hamilton

- Hastings

- Nelson

- New Plymouth

- Palmerston North

- Rotorua

- Tauranga

- Wellington

- Whangārei

VHNZ Whangārei Training Centre

22 Dyer Street, Raumanga, Whangarei

For all enquiries phone 09 242 2615

Or click here to contact your

local Account Manager

VHNZ Albany Training Centre

Unit 7, 18 Corinthian Drive, Albany, Auckland

For all enquiries phone 09 242 2615

Or click here to contact your

local Account Manager

VHNZ East Tāmaki Training Centre

7A Echelon Place, East Tāmaki, Auckland

For all enquiries phone 09 242 3016

Or click here to contact your

local Account Manager

VHNZ Takanini Training Centre

51 Rangi Road, Takanini, Auckland

For all enquiries phone 09 242 2617

Or click here to contact your

local Account Manager

VHNZ Hamilton Training Centre

17 Brent Greig Lane, Burbush, Hamilton

For all enquiries phone 07 242 4235

Or click here to contact your

local Account Manager

VHNZ Tauranga Training Centre

246 Matakokiri Drive, Tauriko, Tauranga

For all enquiries phone 07 242 4209

Or click here to contact your

local Account Manager

VHNZ Rotorua Training Centre

43 Tallyho Street, Mangakakahi, Rotorua

For all enquiries phone 07 242 4291

Or click here to contact your

local Account Manager

VHNZ Hastings Training Centre

121 Stoneycroft Street, Camberley, Hastings

For all enquiries phone 07 242 4168

Or click here to contact your

local Account Manager

VHNZ Palmerston North Training Centre

10-12 Edgeware Road, Palmerston North

For all enquiries phone 07 242 4168

Or click here to contact your

local Account Manager

VHNZ New Plymouth Training Centre

Unit 5, 60 Connett Road, Bell Block, New Plymouth

For all enquiries phone 07 242 0352

Or click here to contact your

local Account Manager

VHNZ Lower Hutt Training Centre

24A Peterkin Street, Taitā, Lower Hutt

For all enquiries phone 04 939 2669

Or click here to contact your

local Account Manager

VHNZ Upper Hutt Training Centre

16 Nicolaus Street, Trentham, Upper Hutt

For all enquiries phone 04 939 2669

Or click here to contact your

local Account Manager

VHNZ Nelson Training Centre

1 Sharps Lane, Nelson South, Nelson

For all enquiries phone 07 242 4213

Or click here to contact your

local Account Manager

VHNZ Christchurch Training Centre

16-18 Klondyke Drive, Hornby South, Christchurch

For all enquiries phone 03 242 0563

Or click here to contact your

local Account Manager

VHNZ Cromwell Training Centre

Unit 2, 4a Ree Crescent, Cromwell

For all enquiries phone 07 242 4167

Or click here to contact your

local Account Manager

OurAccreditations

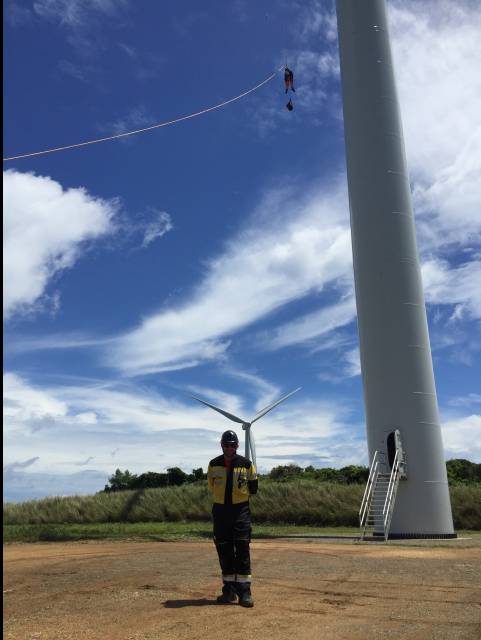

The VHNZ promise of Safety Certainty is reinforced by our qualifications and accreditations.

Meridian

Prepare to advance

in safety with certainty

- Training solutions made to fit your needs.

- Upskill people and train to gain qualifications.

- Personal development and career pathways.

- In-person training in a safe environment.

- Online learning and digital platforms.

We’re in business to help reduce risk, keep people safe and to give opportunities for the future.

Sign up to receive our latest news and keep up to date on industry insights.